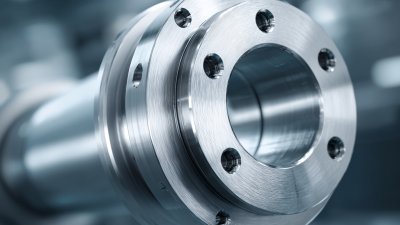

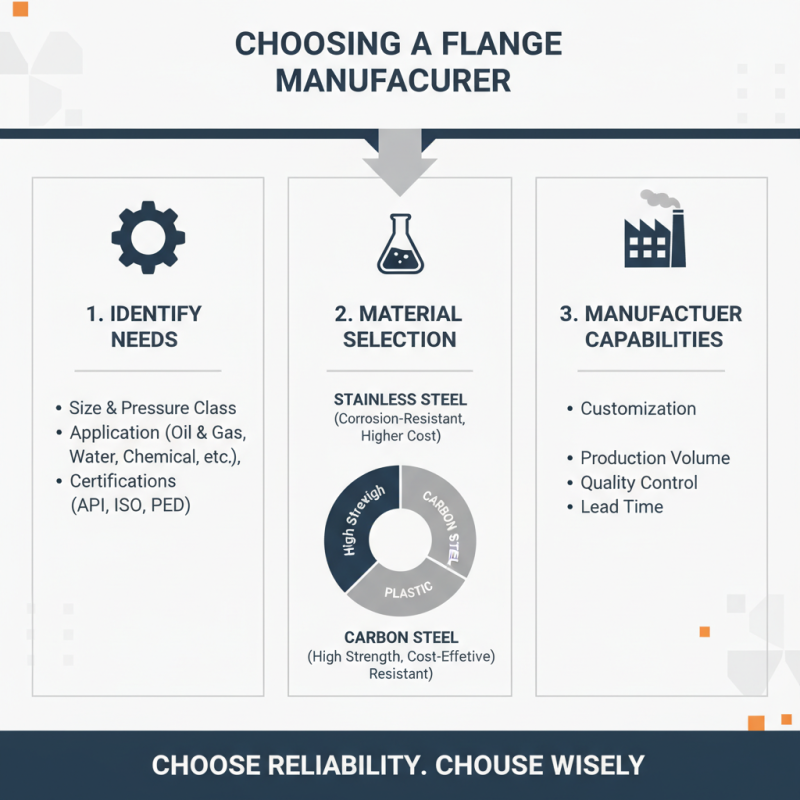

Choosing the right flange manufacturer is crucial for your project's success. With numerous manufacturers available, the selection process can be overwhelming. The ideal manufacturer should meet your specific requirements. Quality, price, and delivery times are vital factors to consider.

You may find that not all manufacturers produce flanges to the same standards. Some prioritize speed over quality. This can lead to costly issues down the line. Take time to research their production practices. Examine their materials and inspect previous work. It’s worth remembering that a lower price might compromise the flange’s durability.

Furthermore, communication plays a key role in your partnership. A responsive manufacturer fosters a better working relationship. This ensures that your needs are met effectively. Taking these factors into account can help you make an informed decision. A well-chosen flange manufacturer can save you time and money in the long run.

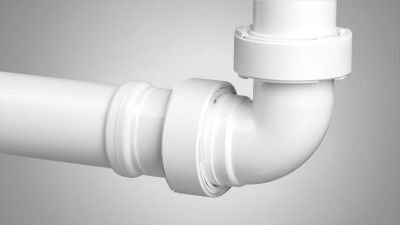

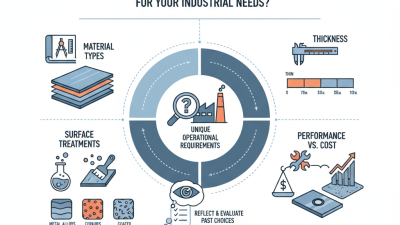

When choosing a flange manufacturer, identify your specific needs first. Consider the materials you require. Common options include stainless steel, carbon steel, and plastic. Each material has its advantages and drawbacks. For example, stainless steel is corrosion-resistant but can be more expensive.

Size and dimensions are crucial. Ensure that the manufacturer can provide flanges that fit your project specifications. Do you need standard sizes or custom dimensions? Review industry standards relevant to your project. API, ASME, and DIN are common standards that may apply to your flanges.

**Tip:** Always request documentation for the materials used. It helps ensure quality and compliance with standards.

Communication is vital. Discuss your requirements with potential manufacturers. Ask them about their production capabilities, lead times, and quality control measures. Not all manufacturers offer the same level of service. Some may not meet your expectations, leading to project delays.

**Tip:** Visit the manufacturer's facility, if possible. Seeing their operations can help in making an informed choice. Remember, taking time to evaluate your needs can save you trouble later.

When selecting a flange manufacturer, evaluating their experience and industry reputation is crucial. A manufacturer with over 20 years in the industry tends to have valuable insights. For example, according to a recent survey by the Industrial Flanges Association, 75% of successful projects involve manufacturers who have been in the market for a decade or more. Longevity often translates to expertise in production techniques and knowledge of material quality.

Moreover, examining a manufacturer's reputation can reveal much about their reliability. A study indicated that 65% of customers prioritize previous client feedback when choosing a supplier. Companies that have consistently delivered high-quality products receive more positive reviews. Consider looking at case studies or client testimonials that detail the manufacturer's work. If previous projects show delays or quality issues, it's a red flag.

While experience is essential, it's wise to reflect on the extent of a manufacturer's specialization. A broad range of flanges may indicate versatility, but it doesn't always ensure quality. Some manufacturers struggle with maintaining standards across diverse products. Focusing on those that specialize in specific flange types or industries might yield better results. Even well-known entities might falter in niche markets, emphasizing the need for careful assessment.

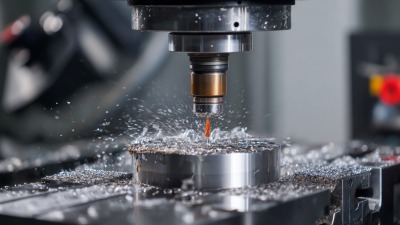

When selecting a flange manufacturer, quality assurance and certification processes are vital. A robust quality assurance plan ensures that products meet industry standards. Look for manufacturers with ISO certification, as this indicates a commitment to quality management. Check if they apply regular testing to their products. Testing can include pressure tests and material integrity assessments.

Tips: Review the manufacturer’s testing methods. Do not hesitate to ask for documentation. This transparency shows their confidence in product quality.

Certification processes reflect a company's dedication to maintaining standards. Verify if the manufacturer complies with relevant industry norms. Certifications like ASME and ASTM can assure product reliability. Remember, quality starts in the production phase, not after.

Tips: Compare certifications among manufacturers. It's essential to recognize the difference between them. Quality assurance should not be an afterthought for any manufacturer. Evaluate their commitment today to avoid pitfalls later.

When selecting a flange manufacturer, pricing and lead time play a critical role. Many manufacturers offer various pricing structures. Some may provide bulk discounts, while others have fixed rates regardless of order size. It’s vital to request quotes from multiple sources. A spreadsheet can help you compare these prices easily, ensuring you find the most cost-effective option.

Lead time varies significantly between manufacturers. Some may promise quicker turnaround but at a higher cost. Others might offer competitive prices but require longer lead times. It's essential to consider your project timeline. Missing a deadline can lead to more costly delays down the line. Regular communication with manufacturers can uncover whether they can expedite orders if necessary.

Reflecting on your unique needs is important. Sometimes, the cheapest option may compromise quality or service. Don’t rush this process. Analyzing pricing alongside lead times can lead to better decision-making. Prioritize the aspects that matter most to your project. Investing time in this evaluation can save you headaches in the future.

| Manufacturer Location | Material Type | Price Range (per unit) | Lead Time (weeks) | Min Order Quantity |

|---|---|---|---|---|

| USA | Carbon Steel | $5 - $15 | 2 - 4 | 50 |

| Germany | Stainless Steel | $10 - $25 | 3 - 5 | 100 |

| China | Alloy Steel | $4 - $12 | 4 - 6 | 200 |

| India | PVC | $1 - $5 | 8 - 10 | 1000 |

| Brazil | Copper | $15 - $30 | 5 - 7 | 20 |

When selecting a flange manufacturer, customer support is often overlooked. Strong support can make a significant difference. A recent industry report indicated that 73% of customers value timely responses from manufacturers. Quick replies help address potential issues early on. Manufacturers with dedicated support teams tend to have higher satisfaction rates.

After-sales service is equally critical. According to a survey, 68% of customers consider post-purchase support when choosing a manufacturer. Many flanges require maintenance or adjustments after installation. If a manufacturer fails to provide effective service, customers may experience delays. This could lead to costly downtimes in projects.

Some manufacturers might promise comprehensive support but deliver inadequate service. It's vital to read reviews and seek customer testimonials regarding their experiences. If a company lacks transparency about their after-sales process, it could be a red flag. The goal is to choose a manufacturer that prioritizes customer needs, especially after the sale is made.