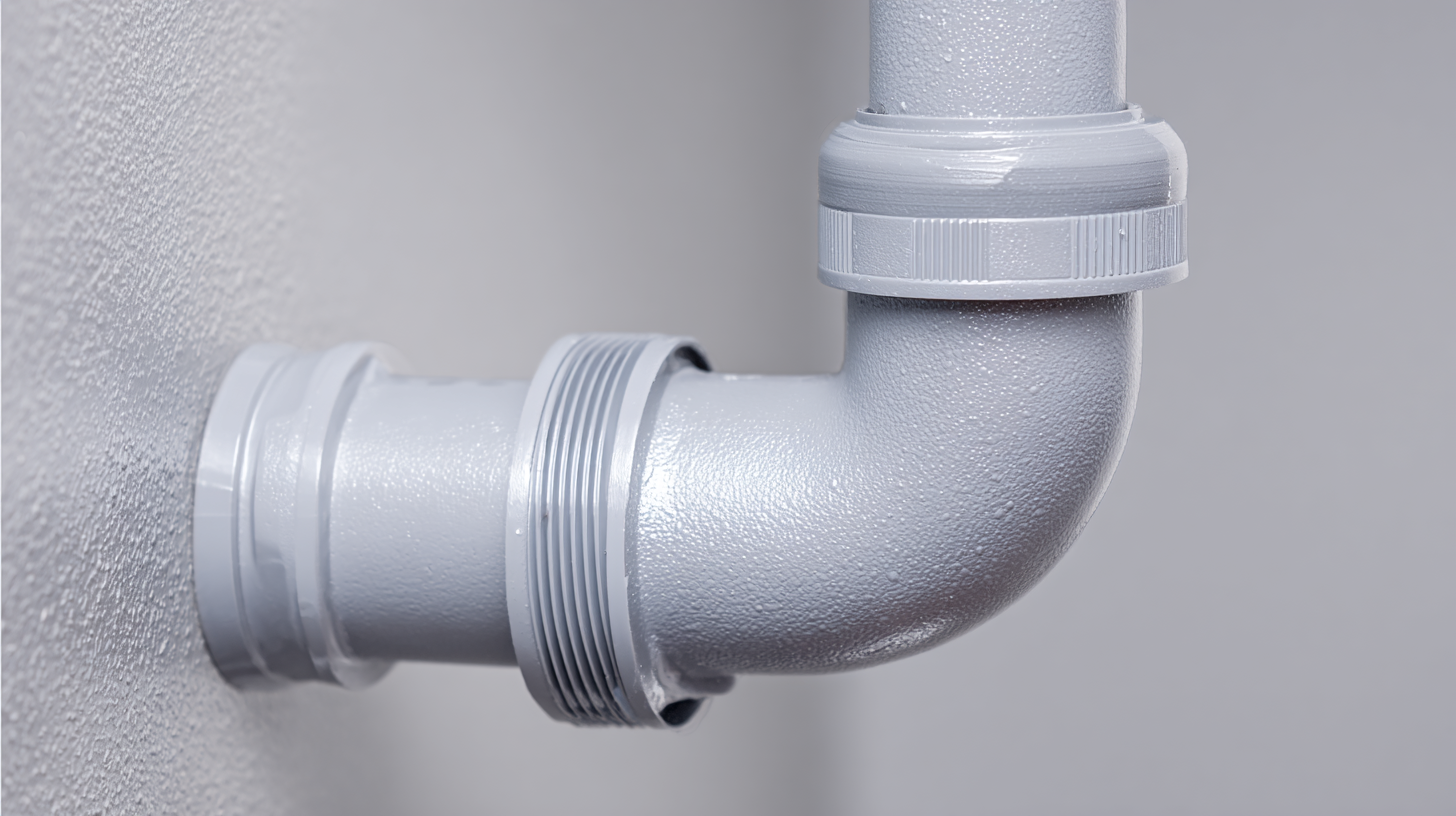

In the realm of plumbing and fluid management, selecting the appropriate fittings is crucial for ensuring maximum efficiency and performance. One essential component in this category is the PVC Elbow With Thread, which plays a pivotal role in creating seamless bends and connections within piping systems.

According to the Plastics Pipe Institute, PVC fittings, including threaded elbows, account for over 60% of the market in plumbing applications due to their durability, resistance to corrosion, and cost-effectiveness. Furthermore, a report from Markets and Markets highlights that the global PVC market is projected to reach $78.86 billion by 2026, underscoring the widespread adoption of PVC materials in various sectors. As such, choosing the right PVC Elbow With Thread not only impacts system efficiency but also contributes significantly to the longevity and reliability of plumbing installations.

When selecting the appropriate PVC elbow with thread, it is crucial to understand the various types available in the market. The most common types include 45-degree and 90-degree elbows, each serving distinct purposes in piping systems. A 90-degree elbow is typically used for changing the direction of flow swiftly, making it suitable for corners and tight spaces. Conversely, a 45-degree elbow allows for a more gradual bend, reducing flow resistance and turbulence, which can be beneficial in high-velocity applications.

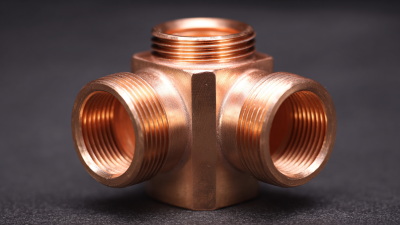

In addition to angle variations, PVC elbows can also differ in terms of threading, such as male and female threads, which determine how they connect to other piping components. Male-threaded elbows are designed to screw into a female-threaded fitting, while female-threaded elbows can accept male-threaded pipes. Understanding these distinctions is essential for ensuring compatibility within your piping system. Moreover, considering factors such as pressure ratings and material quality can significantly influence the efficiency and longevity of your plumbing setup.

When selecting a PVC elbow with thread, understanding the variety of thread types available is crucial for ensuring optimal compatibility with your existing piping system. The two primary thread types commonly encountered are NPT (National Pipe Tapered) and BSP (British Standard Pipe). NPT threads are characterized by their tapered design, which allows for a tighter seal as the connection is tightened, making them ideal for a range of applications, particularly in the United States. In contrast, BSP threads, which are parallel, are primarily used in Europe and Asia, providing a flat surface that can work well with various sealing methods, such as rubber washers or thread sealants.

It is also essential to consider the material compatibility of the threaded connections. PVC is widely used due to its resistance to corrosion and chemical degradation, but factors such as the temperature and type of fluid being transported can affect performance. When assessing the compatibility of a threaded PVC elbow, ensure that the thread type aligns with your system's requirements and that the materials can withstand the intended pressures and temperatures. This attentiveness to thread specifications will not only enhance the efficiency of your piping system but also prolong its lifespan, minimizing maintenance and repair needs.

When selecting a PVC elbow with threads, assessing the size and diameter is crucial for ensuring efficient fluid flow. An improperly sized elbow can lead to turbulence, increased pressure drops, and ultimately reduced system efficiency. Therefore, it’s essential to match the elbow size to the pipe diameter, as this will optimize flow characteristics and maintain the fluid velocity required for your application.

Additionally, consider the type of fluid being transported when determining the appropriate diameter. For example, viscous liquids may require a larger diameter to reduce resistance and promote smoother flow. It is also vital to account for any fittings or accessories that will impact the overall system design. By carefully evaluating these factors and choosing the right size and diameter for your PVC elbow, you can maximize performance and longevity in your piping system.

When selecting the right PVC elbow with thread, material quality plays a crucial role in ensuring longevity and optimal performance. High-grade PVC not only offers durability but also enhances resistance to environmental factors. For instance, recent studies indicate that subpar materials can lead to significant performance degradation in various applications, similar to the losses observed in photovoltaic systems due to inadequate component quality. Choosing a PVC elbow made from quality materials can mitigate potential performance issues and extend the product's lifespan.

To maximize efficiency, consider the following tips: first, prioritize elbows made from UV-resistant PVC, which can withstand exposure to sunlight without becoming brittle over time. Additionally, verify that the threading is crafted with precision to prevent leaks, as improper threading can lead to system inefficiencies. Lastly, look for certifications from recognized industry bodies, which can serve as an assurance of material quality and performance standards. By paying close attention to these aspects, you can ensure that your choice of PVC elbows contributes positively to your overall system efficiency and durability.

| Tip Number | Tip Description | Material Type | Longevity (Years) | Performance Rating |

|---|---|---|---|---|

| 1 | Choose high-grade PVC material for durability. | Type 1 PVC | 10 | Excellent |

| 2 | Check for UV resistance for outdoor applications. | UV-Stabilized PVC | 8 | Very Good |

| 3 | Select appropriate thread type for secure fittings. | Threaded PVC | 12 | Good |

| 4 | Evaluate chemical resistance for specific applications. | Chemical-Resistant PVC | 15 | Excellent |

| 5 | Look for certifications (ASTM, ISO) to ensure quality. | Certified PVC | 20 | Outstanding |

| 6 | Assess the pressure rating for the intended use. | High-Pressure PVC | 10 | Very Good |

| 7 | Consider the fitting angle and flow efficiency. | Standard PVC | 8 | Good |

When selecting a PVC elbow with thread,

it's crucial to consider both temperature and pressure ratings to ensure optimal performance in your plumbing system. PVC elbows are engineered to handle specific conditions; exceeding these limits can lead to leaks or failures. Carefully consult product specifications and ensure the ratings align with the operational requirements of your system.

One tip for maximizing efficiency is to choose PVC elbows specifically rated for the temperature and pressure you'll encounter. For high-temperature applications, opt for enhanced PVC materials that can withstand elevated heat without deforming. Additionally, assess the pressure ratings and select fittings that provide a safety margin above your system’s maximum expected pressure.

Another essential tip is to evaluate the compatibility of the PVC elbow with other materials in your plumbing network. If you’re integrating with metal piping, consider using transitions or specific thread types to alleviate stress and prevent corrosion. This careful coordination of materials and ratings will enhance the longevity and efficiency of your plumbing setup, ultimately reducing maintenance costs.