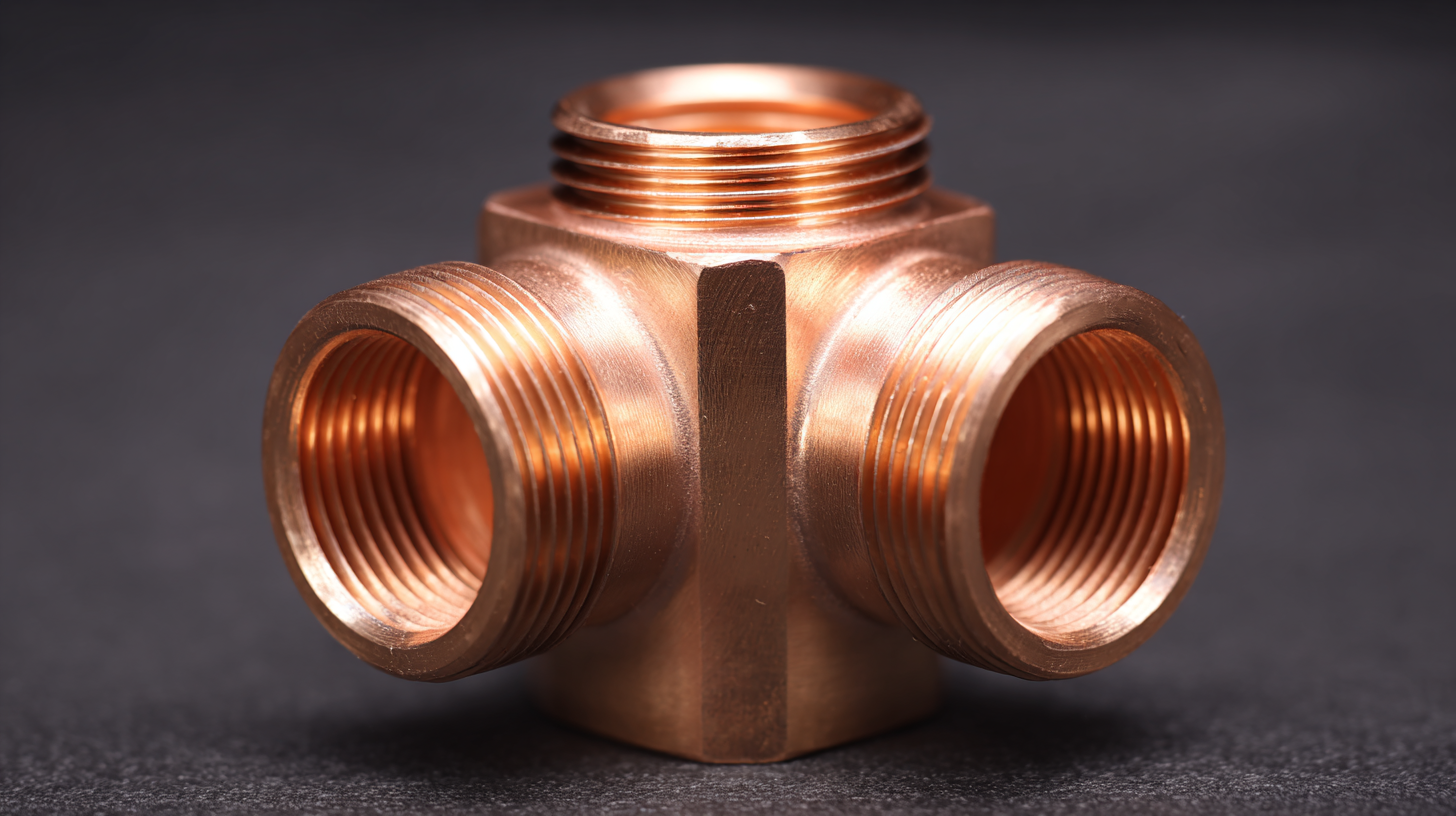

As the 2025 China Import and Export Fair approaches, the demand for innovative solutions in the plumbing and HVAC industries has surged, with a particular emphasis on high-performing components such as Copper Elbow Fittings. According to a recent market research report by Grand View Research, the global copper pipe and fitting market size is projected to reach USD 31.5 billion by 2027, growing at a CAGR of 5.5% from 2020 to 2027. This growth is driven by increasing urbanization, infrastructure development, and the need for efficient heating and cooling systems, where Copper Elbow Fittings play a crucial role in ensuring optimal flow and durability. As manufacturers prepare for the fair, it becomes imperative to not only meet rising market demands but also to showcase advancements in product design and sustainability. This pivotal event serves as an arena for stakeholders to drive innovation, highlighting the importance of Copper Elbow Fittings in modern construction and residential applications.

The copper elbow fittings market is witnessing a transformative wave of innovations as we approach the 2025 China Import and Export Fair. With an increased demand for high-quality plumbing and HVAC solutions, manufacturers are focusing on developing advanced materials and designs that enhance performance and sustainability. Smart manufacturing technologies, such as 3D printing and automated quality control, are being integrated into the production process, allowing for greater precision and efficiency. As a result, the durability and cost-effectiveness of copper elbow fittings are significantly improved, catering to the evolving needs of consumers.

The copper elbow fittings market is witnessing a transformative wave of innovations as we approach the 2025 China Import and Export Fair. With an increased demand for high-quality plumbing and HVAC solutions, manufacturers are focusing on developing advanced materials and designs that enhance performance and sustainability. Smart manufacturing technologies, such as 3D printing and automated quality control, are being integrated into the production process, allowing for greater precision and efficiency. As a result, the durability and cost-effectiveness of copper elbow fittings are significantly improved, catering to the evolving needs of consumers.

Additionally, emerging trends such as eco-friendly practices and the use of recyclable materials are reshaping the industry. Companies are exploring alternative copper alloys that not only meet performance standards but also reduce environmental impact. This shift towards sustainable product development aligns with global efforts to promote green building practices. As we approach the fair, manufacturers are poised to showcase these innovative solutions, highlighting their commitment to quality and sustainability while addressing the increasing market demand for reliable and efficient plumbing fittings.

The demand for copper fitting requirements is being driven by several key factors, primarily linked to the booming automotive sector and the overall growth of the construction industry. As the market for faucets in the United States is projected to grow from $6.27 billion in 2025 to $9.38 billion by 2032, with a compound annual growth rate of 5.9%, the need for efficient and durable copper fittings is becoming increasingly critical. The automotive industry, in particular, has demonstrated a rising appetite for non-ferrous metals, including copper, due to their essential role in manufacturing both traditional and electric vehicles.

Additionally, the recent surge in copper prices, attributed to its status as an industrial barometer, reflects heightened global demand for this versatile metal. The dynamics of the copper market are interconnected with broader economic cycles and technological advancements, such as the rise of electric vehicles and increased use of printed circuit boards in consumer electronics. These developments are likely to sustain the momentum for copper elbow fittings, influencing market requirements and production strategies in the coming years.

| Market Segment | Market Demand (Units) | Growth Rate (%) | Key Influencing Factor |

|---|---|---|---|

| Residential Construction | 1,200,000 | 8.5 | Increased Housing Starts |

| Commercial Plumbing | 800,000 | 6.2 | Growth in Commercial Projects |

| Industrial Applications | 500,000 | 5.0 | Expansion of Manufacturing Sector |

| Infrastructure Projects | 600,000 | 7.3 | Government Investments |

| HVAC Systems | 300,000 | 4.5 | Rising Demand for Energy Efficiency |

The manufacturing of copper elbow fittings is evolving to meet the pressing demands for sustainability in the industry, particularly as we approach significant platforms like the 2025 China Import and Export Fair. Efforts are being made to integrate eco-friendly practices throughout the production process, ensuring that the materials used not only comply with environmental standards but also contribute positively to greener outcomes. This shift towards sustainable manufacturing is critical as the market increasingly prioritizes environmentally responsible products.

Innovations in the production techniques of copper elbow fittings can significantly impact the overall sustainability of the plumbing and construction sectors. By focusing on the lifecycle of materials and reducing waste, manufacturers are set to enhance their offerings while fostering a culture of sustainability. Additionally, these practices align with the global trend towards sustainable resource management, echoing the broader shifts seen in other industries, such as fashion, where companies are now exploring sustainable textiles and eco-friendly production methods. The proactive stance taken by copper fitting manufacturers underscores a collective commitment to creating a greener future while responding to the heightened market demand for sustainable solutions.

As the global demand for copper elbow fittings continues to surge, companies are compelled to adapt their competitive strategies to navigate changing market conditions. According to a recent industry report by Grand View Research, the global copper fittings market is projected to reach USD 18.8 billion by 2028, growing at a CAGR of 5.3%. This growth is driven by the rising demand in construction and plumbing sectors, which in turn influences how manufacturers position themselves within the market.

To remain competitive, companies are leveraging advanced technologies such as automated manufacturing processes and smart inventory management systems. These strategies not only enhance efficiency but also reduce lead times, which is critical in meeting customer expectations. On top of that, establishing strategic partnerships and focusing on sustainable practices have become pivotal in attracting eco-conscious consumers.

**Tips:** Invest in research and development to innovate product design and improve material efficiency. Additionally, engage in continuous market analysis to identify emerging trends early, allowing your company to pivot quickly and offer relevant solutions. Lastly, enhance your digital marketing strategies to effectively communicate your unique value proposition to a wider audience.

This bar chart illustrates the projected market demand for copper elbow fittings from 2021 to 2025, highlighting a steady growth trend in response to increasing construction and manufacturing activities across various sectors.

At the 138th China Import and Export Fair, running from October 15 to November 4, 2025, the spotlight is on the evolving landscape of copper elbow fittings amid rising market demand. This prestigious fair, with over 74,600 booths and more than 32,000 exhibitors—setting a historic record—serves as a vital platform for showcasing innovative products. The shift towards intelligent manufacturing is particularly noted, with many exhibitors unveiling advanced solutions to meet the increasing global demand for quality copper fittings.

Industry reports indicate that the copper products market is projected to grow significantly, driven by advancements in technology and sustainability measures. As market dynamics evolve, manufacturers are keen to demonstrate their capabilities in producing high-performance, eco-friendly fittings that cater to diverse applications ranging from plumbing to electrical systems. The fair illustrates the commitment of companies to enhance their product offerings, particularly in regions recognized for their manufacturing prowess, as they align with broader trends in globalization and technological innovation.